Battery Tester Buying Guide

Battery failure is the leading cause of vehicle breakdowns, accurate testing can allow you to make informed decisions to ensure vehicles are not leaving with a discharged or dead battery. By implementing a testing programme, battery replacements can be avoided, saving you time, effort and money. Now is the perfect time to invest in new battery diagnostic equipment and to start the year as you mean to go on.

Finding the right battery tester can be difficult. Using our extensive experience, we have compiled a battery tester buying guide to help you find your next tester.

The EXP1000FHD: A heavy-duty, reliable and compact battery tester.

The EXP1000 Fleet Heavy Duty battery tester is a tried and tested unit, supporting both 12v and 24v fleet workshop applications – the clue is literally in the name!

Manufactured by leading industry manufacturer Midtronics, the EXP1000FHD tests batteries to an industry standard used by main dealers and vehicle manufacturers around the world. It’s no surprise it’s a best seller amongst emergency service, public service vehicle, and other fleet workshops.

The EXP-1000FHD incorporates features that are a must for most fleet and heavy duty workshops. This tester has the unique ability to carry out 24v battery and electrical system testing whilst in a set. EXP-1000FHD also gives you the ability to balance the 2 batteries in the 24v set.

For record keeping, EXP1000FHD records vehicle registrations, fleet numbers, and chassis numbers, a feature that is absent from other testers on the market. It also identifies whether any excessive parasitic drains are present on a battery, by using an amp clamp. Technicians are also able to take the tester wherever they need due to its portable size and ergonomic shape.

Combine the tester with a wireless SD card and you can access our industry leading battery management online portal, ROBIS (Rotronics Online Battery Information System). We built ROBIS from the ground up to support workshops in identifying where issues are in their battery management programme. Since then workshops have saved thousands by drastically reducing the amount of battery replacements. Fitted with features such as, instant warranty claims, early battery issue detection, easy to understand reports and much more. ROBIS can revolutionise your battery management programme.

The CPX900: An advanced, modern, and updatable battery tester.

CPX900 is the latest platform available from Midtronics and incorporates the most advanced battery testing algorithms and software diagnostic capability, delivering faster test results with increased accuracy and unit reliability.

CPX-900 is fitted with features not seen before in such a small, handheld battery tester. This tester not only has the ability to perform battery tests but can also quickly and accurately, diagnose the battery’s cranking and reserve capacity health. This is thanks to the built in load, that measures the battery’s ability to start the vehicle.

CPX-900 allows you to view results in a few different ways, using a print out from the built in printer, emailed results over WiFi or allow test results to instantly upload to ROBIS (Rotronics Online Battery Information System).

Unlike other products in the market, the CPX900 can wirelessly download new software updates, so technicians always have access to the best software and features available. The unit is just as portable as the EXP1000FHD, providing test support wherever technicians need it.

The DCA8000: A unique, comprehensive, and fast diagnostic technology.

The DCA8000 Dynamic Diagnostic Charging System is the most comprehensive diagnostic equipment on the market. It is the only diagnostic equipment that has the best of both technologies under one roof, combining both diagnostics and charging to service almost any 12v battery.

In just two minutes or less a defect can be identified, regardless of whether technicians are testing a Flooded, EFB, AGM, GEL or Li-ion battery.

DCA has the ability to also charge a battery after the testing process. By knowing the state of the battery DCA can safely and efficiently charge, eliminating the need for an external charger. Once the battery has been sufficiently charged DCA will alert the technician.

Fitted with a lithium charge mode, 70-amp power supply features and an intuitive touch screen interface, DCA is a simple to use yet powerful. Like the CPX, it can download new software and features wirelessly, also allowing you to send test results straight to your customer.

Which tester is right for your workshop?

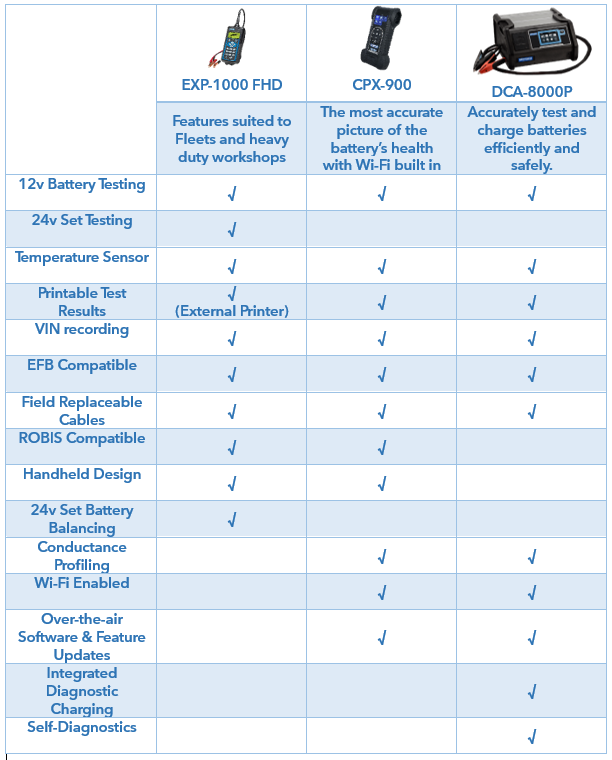

To find the right tester for you and your workshop think about what features you will need most and narrow it down using the below feature table…